Precise Testing to ensure Quality and Performance Compliance.

Our Test Facility demonstrates strong emphasis on in-house product development and product qualification testing to enhance our product offering and to test-bed cutting edge technology.OUR KEY STRENGTH

From hydrostatic testing, gas submerged testing to pressure temperature cycling tests and dynamic cycling tests, the chamber allows for testing of gate valve assemblies across most sizes from 2-1/16” nominal to 7 1/16” nominal and from -46°C to 180°C, 3,000 psi up to 15,000 psi.

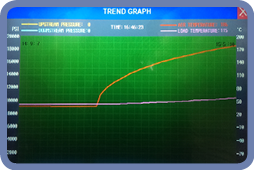

Data Acquisition System for gate valve testing serves as the command and control centre for automating the process of gate valve testing. Test functions such as hydrostatic body test, working and low pressure seat tests, blowdown tests are programmed into the system and the touch screen human machine interface allows for easy control and monitoring during the tests.

TYPE OF TESTS

Hydrostatic Tests are performed for valves and other pressure containing equipment in accordance to API 6A and 17D requirements.

Submerged Gas Tests are performed in our dedicated test pits. Nitrogen is the gas medium used for high pressure tests, pumping valves and other products to pressures of up to 30,000psi.

Dynamic Cycling Tests are performed in accordance to API 6A includes a 600 operating cycles test for valves at ambient conditions. NuStar’s gate valve DAQ system is able to perform endurance cyclic tests by pressuring and opening valves systematically to simulate the valve’s operating cycle.

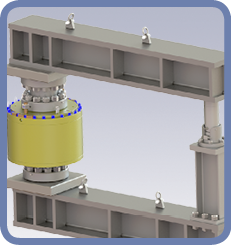

Pressure Temperature Cycling Tests are an integral part of the API 6A Appendix F PR2 qualification process. These are conducted in controlled insulation chambers and are subjected to temperature extremes with our temperature controller and liquid LN2 tanks.

Bend Structure Tests are performed on subsea equipment which are exposed to high bending moments in the environment. Prior to tests, FEA is used to verify the critical planes of the test product when subjected to the required bending moment.